Fixed Bed Reactor ChemEnggHelp

The paper develops a design feasibility study of a multi-tubular polytropic fixed bed reactor for the one-stage ethanol to 1,3-butadiene (ETB) process employing a modified MgO-SiO 2 catalyst. The analysis quantifies the effect of the internal diffusion on scaling up the catalyst activity and selectivity by considering a complex chemistry of seven parallel/series reactions described by detailed.

(a) The pilot fixed bed reactor; (b) reactor model. Download Scientific Diagram

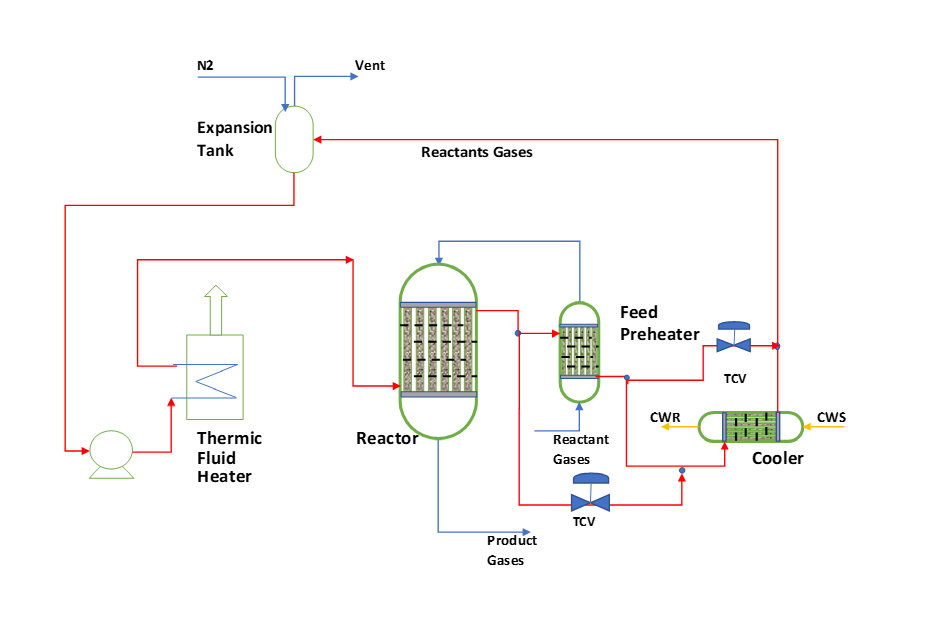

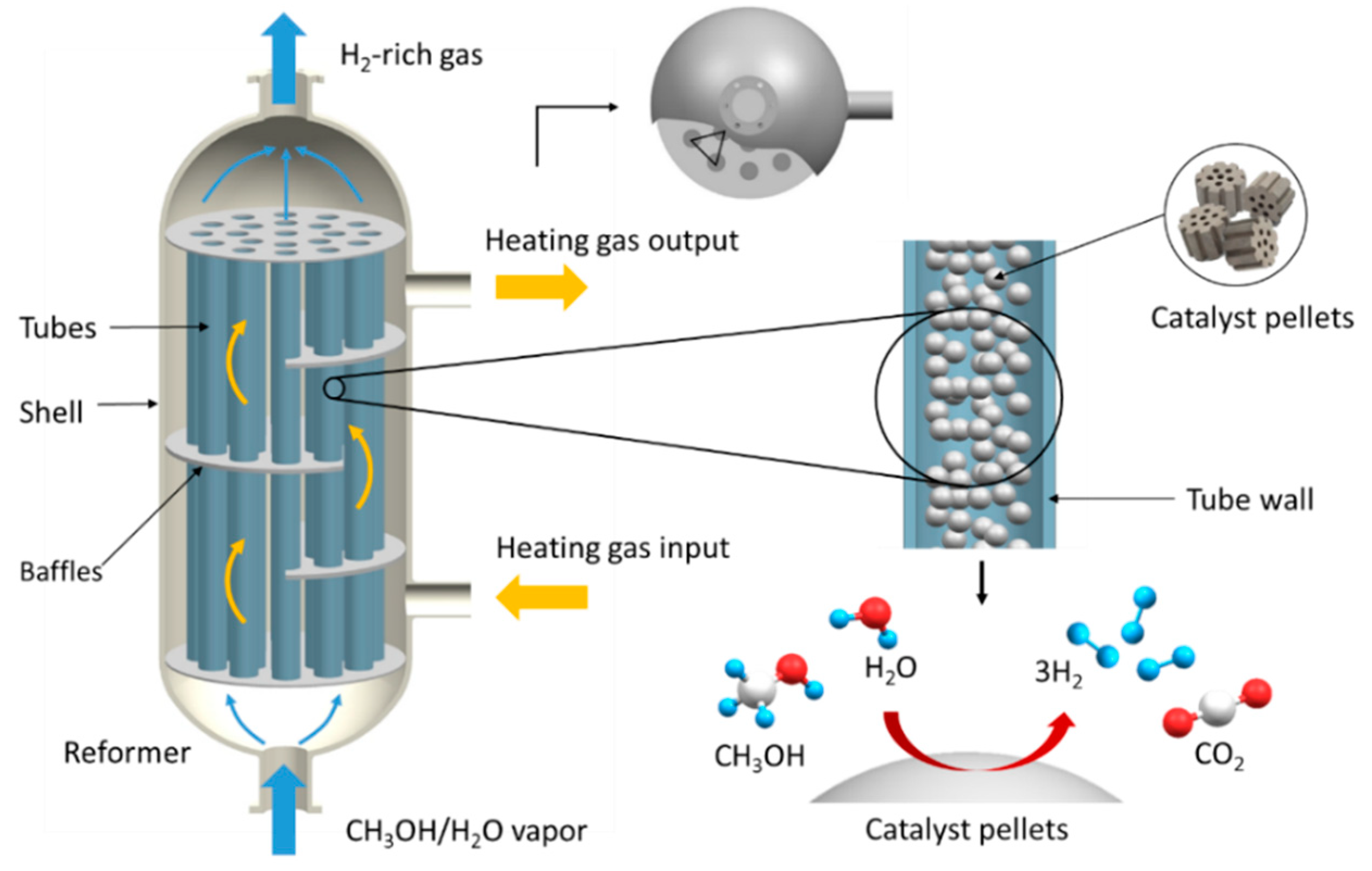

These are the multi-tubular fixed-bed, the slurry reactor, or the fluidized-bed reactor (with either a fixed bed or a circulating bed). The fixed-bed reactor consists of thousands of small tubes with the catalyst as surface-active agent in the tubes. Water surrounds the tubes and regulates the temperature by settling the pressure of evaporation.

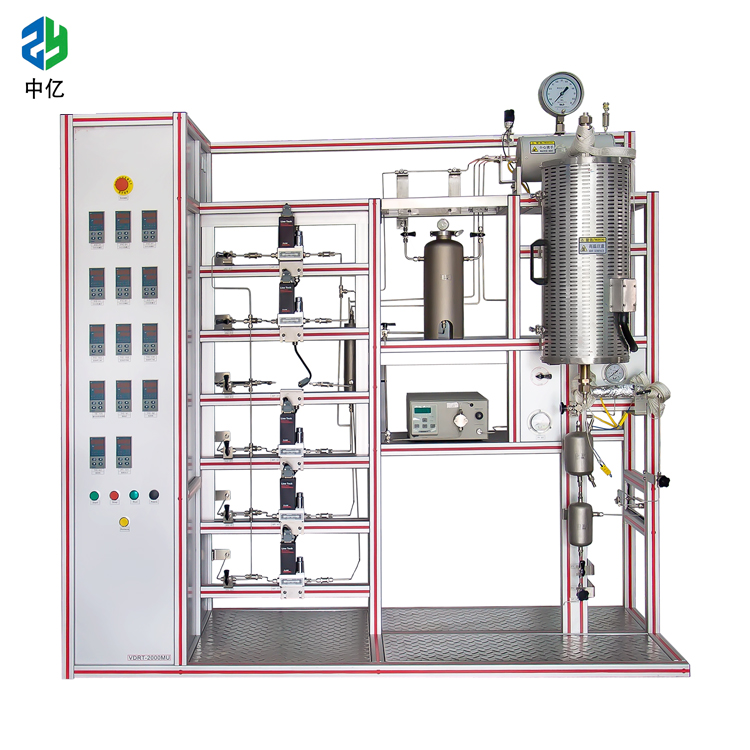

fixed bed reactor /catalyst testing reactor/ FCC/RFCC

In this work, the design and fabrication of a pilot-scale multi-tubular fixed bed reactor have been carried out with the aid of computational software (MATLAB R2010b), aiming to process 6.5 L/h of.

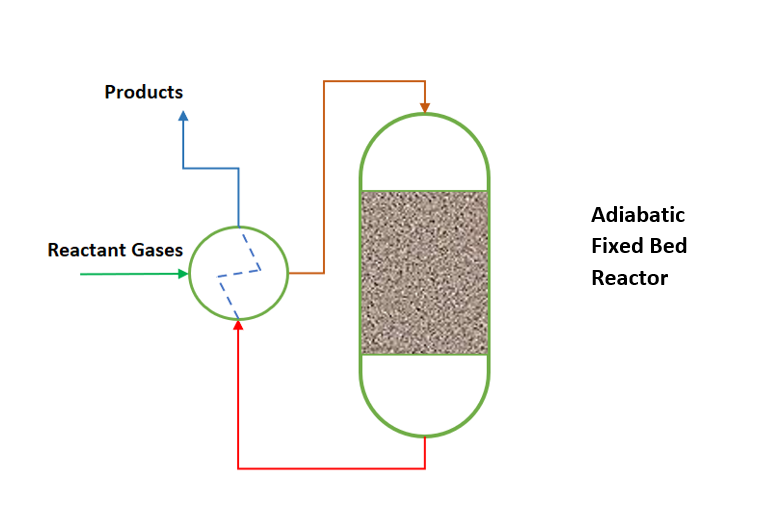

Adiabatic fixedbed reactors Big Chemical Encyclopedia

Residue hydrocracking has been attracting more and more attention to the refining industry in recent years, and one of the best approaches is ebullated bed residue hydrocracking (EBRH). STRONG ebullated bed residue hydrocracking uses a new type of reactor, and a 50 KTA demonstration unit has been put into operation now. Crucial points of STRONG residue hydrocracking are proposed physical and.

Patent US7226567 Multitube fixedbed reactor, especially for catalytic gas phase reactions

The schematic diagram of multi-tubular fixed-bed reactor's model is shown. Fig. 2. (a) Schematic diagram of the novel configuration multi-tubular fixed-bed reactor: 1—fluid inlet; 2—molten salt outlet; 3—circular distributor; 4—fluid outlet; 5—molten salt inlet; 6—baffles; 7—reaction tubes. (b) Grids in the end face of reactor.

FTS fixedbed reactor. a Real photograph, b schematic view Download Scientific Diagram

Multi-tubular fixed-bed heat-exchanger reactors operating under polytropic conditions are attractive for conducting the Sabatier process due to the fact of its cost-effective design. In this reactor approach, the heat of the reaction is transferred from the reactive tube to a coolant.

Adiabatic fixedbed reactors Big Chemical Encyclopedia

Fixed Bed Reactor is a topic that covers the principles, design, and applications of reactors with solid catalysts or adsorbents. Learn from the latest research articles and case studies on topics such as pilot-scale testing, autothermal operation, load-flexible optimization, and direct air capture using fixed bed reactor systems.

Fixed bed Tubular reactors

This work aims to design a multi-tubular fixed-bed reactor, which is able to convert a carbon dioxide stream into Synthetic Natural Gas (SNG) in an optimal manner. For this purpose, carbon dioxide is mixed with hydrogen in stoichiometric ratio ( n ̇ H 2 ∕ n ̇ CO 2 = 4 ∕ 1) and fed to the multi-tubular reactor.

Schematic of the fixed bed reactor system Download Scientific Diagram

TFBR - tubular fixed bed reactor, SPR - slurry phase reactor, MR - microchannel reactor, CFB - circulating fluidized bed reactor, FFB - fixed fluidized bed reactor. 2 CORRECTED PROOF

Energies Free FullText Modeling and Design of a MultiTubular PackedBed Reactor for

reactors with a commercial multi-tubular packed-bed reactor for methanol synthesis. They concluded that the packed-bed reactor had a better performance than structured systems due to the e ective convective heat transfer mechanism in the catalyst bed, which is shown as lower hot-spot temperatures and higher radial heat transfer rates.

Fixed Bed Reactor ChemEnggHelp

This work aims to design a multi-tubular fixed-bed reactor, which is able to convert a carbon dioxide stream into Synthetic Natural Gas (SNG) in an optimal manner. For this purpose, carbon dioxide is mixed with hydrogen in stoichiometric ratio ( ̇H2 ∕ ̇CO2 = 4∕1) and fed to the multi-tubular reactor.

Schematic view of the singletube fixedbed reactor Download Scientific Diagram

possibility of operating SRs with larger reactor tubes diameter, d. t. at fixed total reactor catalyst inventory in view of reducing reactor investment costs. We performed all simulations assuming a safe upper limit for the hot-spot temperature in the catalytic bed of 553 K, which was set as a threshold value for preserving the process.

packed bed reactor design LilahtaroSellers

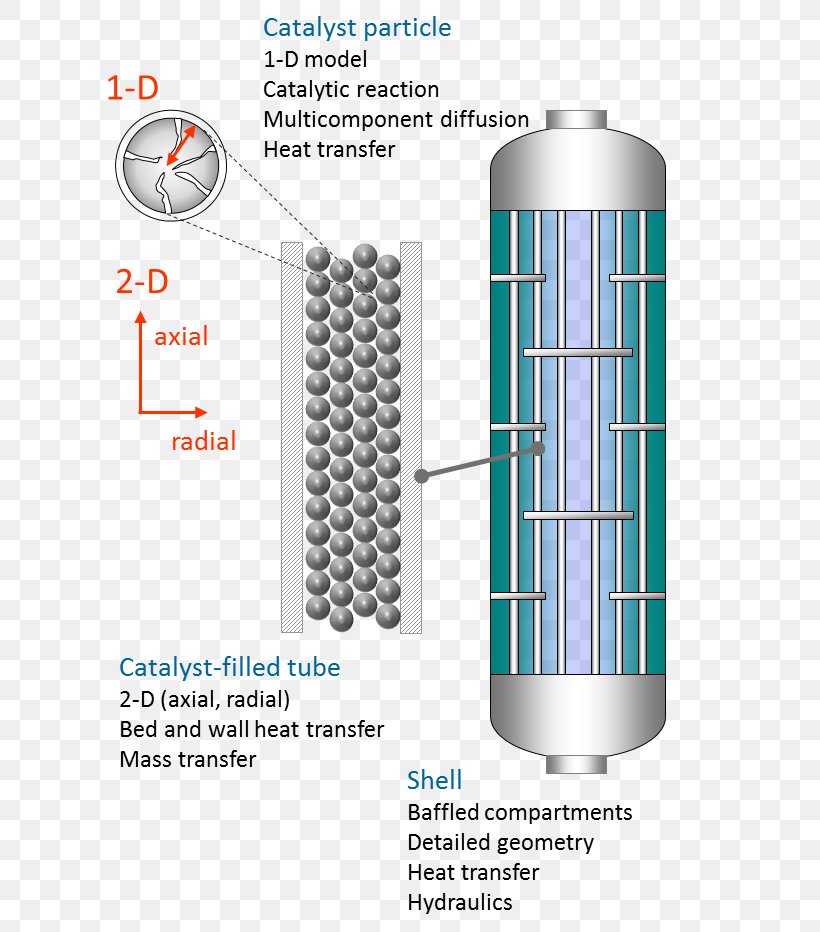

An overall fixed-bed reactor model that combines a one-dimensional plug flow reactor model with a computational fluid dynamics (CFD) model of the shell-side coolant fluid over a series of individual reactor tubes is presented. The model chemistry is the partial oxidation of o-xylene to phthalic anhydride, a well-studied system for reactor performance. The model is used to investigate the.

Fixed Bed Reactor by COMSOL Multiphysics Pvt. Ltd., Fixed Bed Reactor from Bengaluru ID 3497365

The membrane reactor technology, where the steam reforming, water gas shift and hydrogen purification steps all take place in a single reactor, is a promising alternative. Membrane reactor consists of a multi-tubular fixed bed reactor equipped with a hydrogen-selective membrane [58,59]. Methane and steam are fed into the reactor under pressure.

A schematic diagram of the fi xedbed multitubular FTS reactor (a)... Download Scientific Diagram

The power-to-gas (PtG) technology has been known as one of the most viable solutions for storing intermittent renewable energy sources such as solar and wind to the existing gas grid. The chemical CO 2 methanation in a fixed-bed multi-tubular reactor was studied via a multi-scale optimization (MSO) approach covering an one-dimensional plug-flow.

fixed bed reactor /catalyst testing reactor/ FCC/RFCC

The multi-tubular fixed bed reactor is traditionally used for the production of acrolein and acrylic acid from propylene. Commercially the propylene oxidation reaction is accomplished in two stages, namely, propylene oxidation to acrolein followed by acrolein to acrylic acid using different catalysts at each step [].Propylene is one of the most important chemical raw materials and it is widely.